If an Occupational Safety and Health Administration (OSHA) compliance officer came into your clinic right now, would you be prepared?

When it comes to occupational safety and health, a lot of people do not understand the importance of being compliant with proper standards. It is not about getting an okay from an OSHA compliance officer when they come for inspection, rather it is about providing a safe work environment for your team.

While it is best to eliminate hazards, it would not be realistic to eliminate all of them. Some are inevitably present within veterinary hospitals to help administer care to patients.

You may be familiar with some common OSHA requirements, such as no food or drink outside of the break room, secondary label requirements, requiring closed-toe shoes, requiring an eye wash station in the lab, radiation room requirements, proper signage that identifies a hazard, emergency action and prevention plans, and PPE requirements, but where do you start with being compliant? Hospital inspections happen annually to check for compliance, or they can also occur when regulations have changed and following any incident, so there is no time better than the present to start preparing.

By understanding the importance of identifying hazards, creating and implementing a safety plan, and training the team by putting actionable steps into motion, you can create a safer work environment and protect your facility from potential violations.

There are many requirements to being OSHA compliant, but with a few basic tips you can get started. Embark on this journey and ensure the well-being of your team and the overall success of your practice.

Identifying hazards

How do you identify a workplace hazard in the first place? Doing a physical exam or a hazard analysis of your facility will help identify which areas have a high risk for injury or illness. When doing a hazard analysis, think about what can go wrong, where it can go wrong, and what the consequences are for each risk. This step helps identify potential health and safety threats, as well as hazardous situations in a system or environment.

Another way to identify possible hazards is by looking at your team’s job descriptions and doing a job hazard analysis. For example, think of your team members who radiograph patients all day. What can go wrong? What are the consequences? What controls are put in place? Both a hazard analysis and a job hazard analysis should be conducted annually or when getting new equipment and after any environmental or structural changes to the clinic.

During this process, the team’s input is necessary. What a manager considers a hazard can differ from what team members consider depending on where they work and what they do within the facility.

When performing your walkthrough, note potential safety hazards and their location, such as chemicals, trip hazards, ventilation issues, gas leaks, and physical hazards from everyday duties, such as restraining pets.

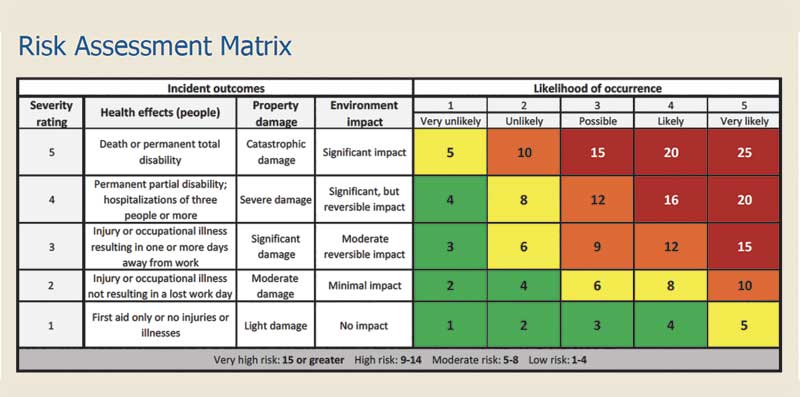

Once you have a hazards list, organize it by categories, which may include surgery, outpatient, inpatient, pharmacy, lobby. Then, assign them a severity rating. This allows you to classify the degree of each hazard and help you prioritize accordingly. A risk assessment matrix (Figure 1) is a helpful baseline in prioritizing potential safety hazards.

Also, having a list of hazardous chemicals on-hand in the facility can be beneficial to keep with the rest of your OSHA documents.

Creating a plan

After identifying potential hazards, create a safety plan to help address them, starting from the most urgent issues to minimize or eliminate.

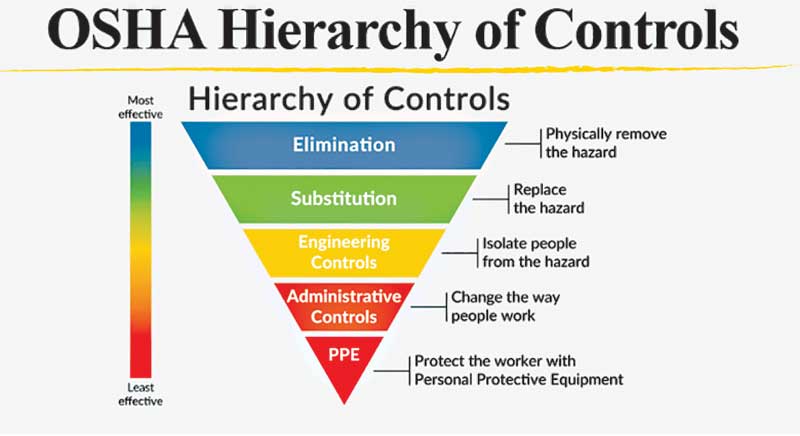

“The OSHA Hierarchy of Controls” (Figure 2) can help create controls to minimize risks. This graph basically states elimination is the most effective way of controlling the hazard whereas PPE is the least effective, and what to do if the hazard is in between.

Elimination is not always feasible, so the next step would be to see if you can substitute or replace it. For example, you cannot substitute or avoid using needles or sharp objects in veterinary medicine, so your next step would be changing the way people work by adding administrative controls. You could provide proper training on handling and disposal of sharps and make a visual reference to post around the sharps containers to help the team remember what is considered a sharp.

Additionally, you can consider having sharps bins in more areas of your clinic, making it more accessible to your staff. PPE is limited for this hazard, so minimizing it by changing the way people work with sharps would be the best option.

By using the OSHA Hierarchy of Controls, you can create your safety plan to minimize any potential hazards that may occur. Make sure to give your team a deadline of when it needs to be fully implemented. By creating a timeline of what changes are happening and when, helps keep your team aware and helps to keep everyone on the same page.

Once finished, use the safety plan to create a manual easily accessible to your team. Consider keeping it in a central location where it can be quickly accessed by any department in the case of an emergency, or when they just need a review of the protocols.

Some employers will keep an electronic safety manual instead and install it on the desktop of every computer in the hospital.

An employer is essentially responsible for creating a safety plan, training the team to minimize the hazard, providing PPE for the team, as well as reporting any hazard-related accident or illness.

The safety plan is what communicates the hazards and includes a standard operating procedure (SOP) that will minimize the exposure to the hazard.

Once you have identified your hazards and created a safety plan, the next step is to train your team, and implement protocols. You will need to reevaluate and adjust according to any changes within the hospital like construction or new equipment.

Onboarding the team

Becoming OSHA compliant does not happen overnight, and a huge part of it is involving the team. Their input is just as important in their help implementing new policies or procedures. The team needs to be aware of the risks and how they can correct or lessen them. Engage your team in training and implementation following your safety plan.

For example, if an employee handles urine samples without gloves, provide extra zoonotic disease training and proper handling training for the whole team.

Another example is acquiring a new diagnostic machine, which would most likely have updated features your technicians have to learn. Involve the team in creating a standard operating procedure for how to use it, so anyone can easily reference it as needed.

Another tip would be to assign someone the role of OSHA safety officer. The OSHA safety officer is essentially responsible for helping create regular annual training for the team, ensuring compliance, actively managing risks, investigating injuries, and keeping up to date on OSHA regulations by navigating them as they change. This is a great way to involve the team and have another set of eyes on the practice.

A great way to knock everything out is assigning one person in each department to help with each correction needed. That person can then delegate any additional needed changes to other team members to get everyone involved. Everybody learns differently so by ensuring the whole team is involved, will help you become OSHA compliant much quicker.

For example, how many clinics out there radiograph their lead personal protective gear annually to check for defects? This is one way you would include in your safety plan as well as your annual staff training, or maybe it goes on an annual checklist to help your team remember. Then you would move forward with training the team on the new operating procedures. Having your managers be involved in creating the safety plan and the rest of the team involved creating training and checklists would be a great example of how to get everyone involved.

After all, the most important part is educating your team on the risks and steps you are taking to correct it or minimize the hazard all while including them. Encourage the team to speak up about potential hazards.

By consistently training and implementing your OSHA safety plan you can create a culture of safety in your facility, ensuring the well-being of your team and the overall success of your organization.

Rachel Singletary is a previous practice manager who has worked in many different areas of veterinary hospitals. Her top passions are inventory, staff development, budgeting, OSHA regulations, and controlled drug record keeping. Singletary enjoys writing and studying new topics in her free time. She is located in Lakeland, Fla.

Reference

- Paoletta, Dave. “How to Implement Your Safety Management System.” Safesite, 9 November 2020, Accessed 28 January 2024.

- Bach, Jonathan. “OSHA Hierarchy of Controls.” MAKESafe Tools, https://makesafetools.com/osha-hierarchy-of-controls/. Accessed 11 February 2024.

- Centers for Disease Control & Prevention.1 “Hierarchy of Controls | NIOSH | CDC.” Centers for Disease Control and Prevention, Accessed 13 February 2024.